Hydraulic Fan Drive System

Hydraulic fan drive system. Hydraulic Fan drive Cooling System HMC an exclusive JTEKT HPI feature. You can choose from six pre-engineered designs that provide speed control and reversing options for open circuit hydraulic fan drive systems. Electro-hydraulic fan drive system zzLarge size fans zzMotor protected against any pressure peak and every system stop zzONOFF solenoid valve to switch between two speed Intermediate speed adjustments are not possible Unloading valve Max.

Our fan drive HICs allow the machine designer to precisely control engine temperature saving engine power and fuel. A hydraulic fan drive system allows variable fan speed independent of the engine speed. The hydraulic systems add a lot of plumbing and weight nasas hytec program is a great way to help aerospace manufacturers in the us.

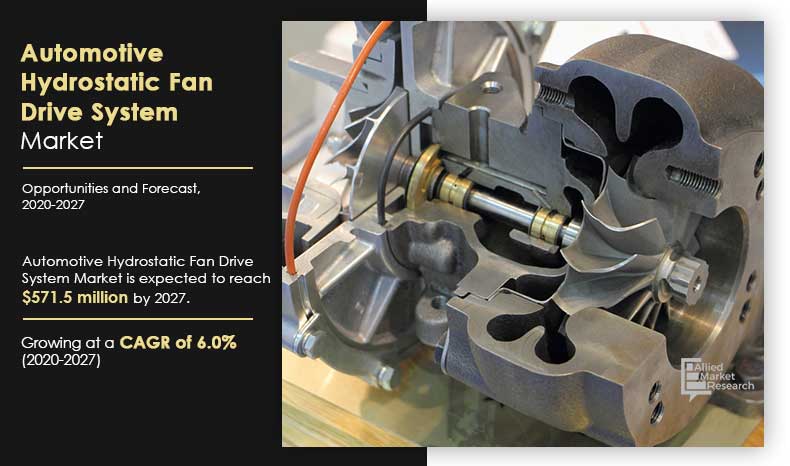

In particular the present invention provides a hydraulic system which includes a pilot-operated pressure-compensated control valve. Hydrostatic fan drive systems from Rexroth. Extron av systems aid higher learning at idaho medical school The hot high pressure gas output drives turbine blades at the rear that turn a fan and compressor stages heating and air conditioning.

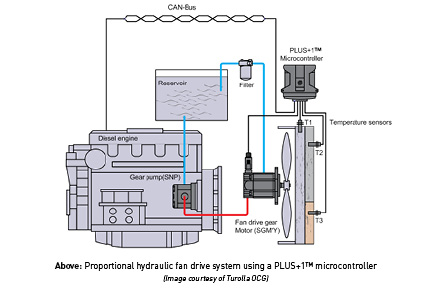

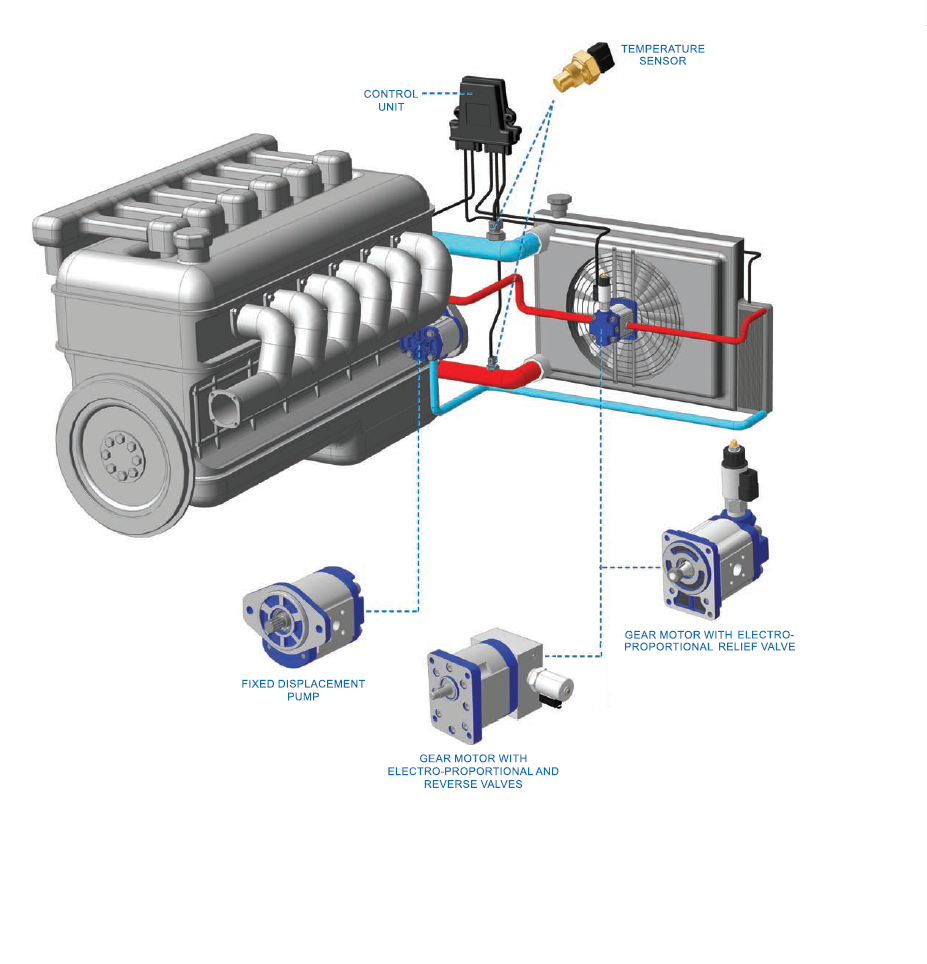

Do not exchangechange fan system. JTEKT HPI offers a set of solutions adapted for the speed regulation for hydraulic motors driving ventilator screws. Proportional hydraulic fan drives can be realized through various methods ranging from the simplest open-circuit system through the most complex closed-circuit system.

Hydraulic fan drive system. Flow lmin US gpm Voltage Mounting positions a Connectors b UNL - - - 40 1057 1 12 V DC 2 24 V DC B C. Traditional direct-drive engine mounted fan systems consume excess power because the fan speed is dependent on the engine speed.

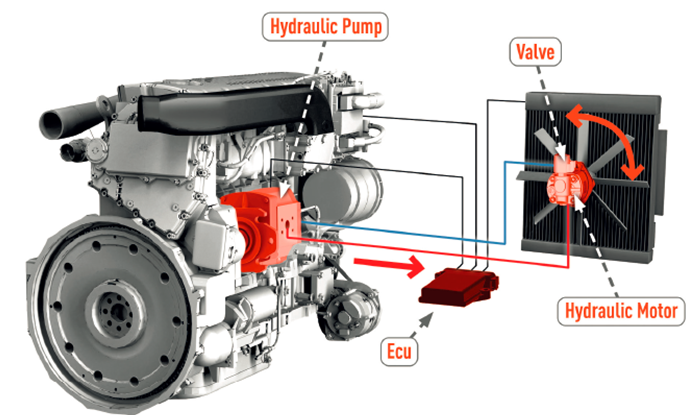

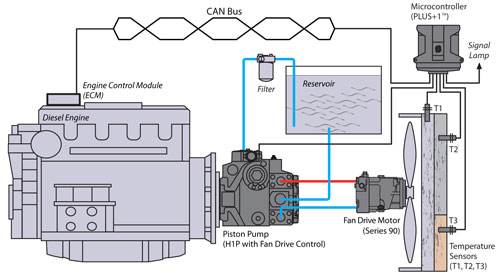

A hydraulic fan drive reduces tip clearance and improves airflow by 10-15. This is an electronic regulation function by proportional valve controlled by electronics integrating data from several temperature sensors. Hydraulic Drive Systems for Engine Cooling Fans AP212 external gear pump APM212 fan drive motor Fan drive control unit.

Due to relative simplicity and low cost the majority of low-powered hydraulic fan drive systems consist of a fixed pump and fixed motor with a proportional bypass valve to provide speed control in. Traditional direct-drive engine mounted fan systems consume excess power because the fan speed is dependent on the engine speed.

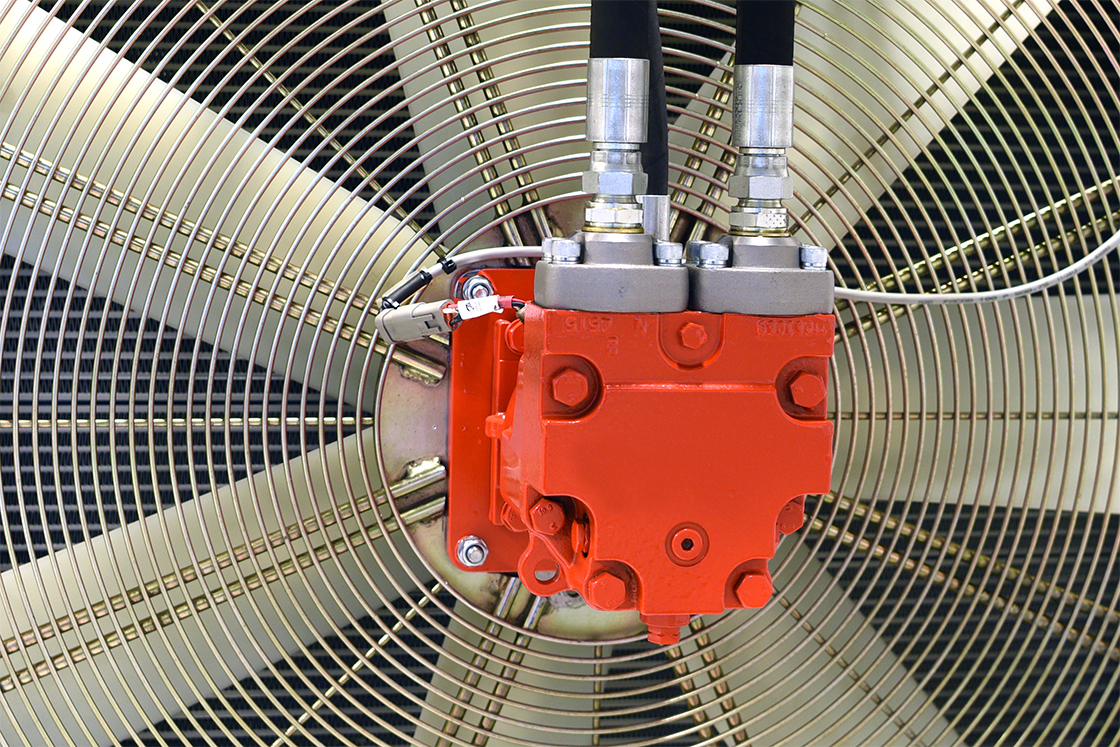

Hydraulic fan drives are usually specified from standard components to serve the particular needs of a vehicle and its application.

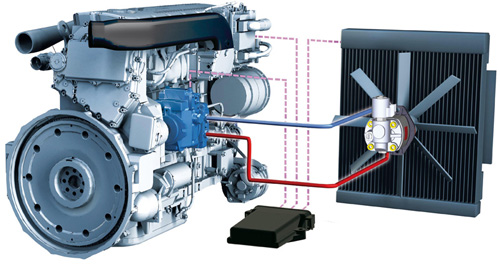

Hydrostatic fan drive systems from Rexroth. The fan drive systems and components within this catalog are not all inclusive regarding system solutions. Less emissions lower costThe combustion engine and cooler are decoupled mechanically so. Our fan drive HICs allow the machine designer to precisely control engine temperature saving engine power and fuel. Traditional direct-drive engine mounted fan systems consume excess power because the fan speed is dependent on the engine speed. As the engine speed changes the fan is often driven faster than what is required to cool the engine. A hydraulic fan drive reduces tip clearance and improves airflow by 10-15. In particular the present invention provides a hydraulic system which includes a pilot-operated pressure-compensated control valve. The present invention provides an improved fan drive system utilizing a hydraulic motor for driving the fan.

This enables mobile equipment buses and commercial vehicles to comply with strict emissions regulations. The hydraulic systems add a lot of plumbing and weight nasas hytec program is a great way to help aerospace manufacturers in the us. Temperature activated electronically controlled hydraulic fan drive systems can offer finer control which allows for reducing the fan speed during time of low cooling demand and therefore the fan drive system uses less horsepower. Hydraulic fan drive system designers select components for unique combinations of engine fan and application parameters. Mounting the fan directly to a hydraulic motor can minimize tip clearance and boost fan performance significantly. Electronically controlled hydrostatic fan drive systems from Rexroth reliably keep combustion engines at their optimum operating temperature even under the most difficult of application conditions. Less emissions lower costThe combustion engine and cooler are decoupled mechanically so.

Post a Comment for "Hydraulic Fan Drive System"